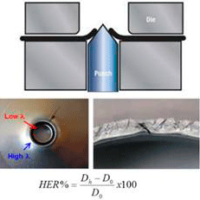

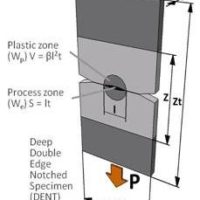

CuttingEdge4.0 RFCS project holistically addresses the edge-cracking problem in AHSS considering fundamental knowledge related to material behaviour, predicting tools and industrial processes and incorporating Industry 4.0 data driven analytics based on Artificial Intelligence (AI) and Machine Learning (ML) expert systems.

The final aim is to transfer to the automotive industry tools and methodologies to predict edge-cracking in the early part design stages, detect edge-cracking defects and assure part quality during forming, boosting the applicability of AHSS-based automotive lightweight parts.